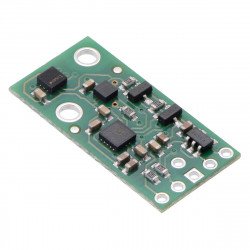

In this category we offer high quality micro Pololu HPCB series motors. The abbreviation is High Power Carbon Brush, which means that the motor is a counterpart of the High Power series with increased capabilities, but uses carbon brushes (created from carbon fibre) instead of those made from precious metals. This type of solution significantly extends the life of the component, thanks to which it is willingly used in devices where replacing the motor is very difficult and the user expects long-term reliability. Pololu is a manufacturer specializing in the production of a wide range of electric motors designed for devices on the borderline of robotics, automation and electronics. The company's products are characterized by very high quality, durability and attention to detail. Pololu micro motors are often used in projects where reliability and small size of individual components are valued.

Pololu micro motors HPCB series - High Power + carbon brushes

HPCB Motor with 298:1 Gear - Pololu 3069

Polol' s miniature high power engine with durable carbon brushes. It has a 298:1 gearbox, speed is 100 rpm, and torque is 5.0 kg*cm (0.49 Nm).HPCB Motor with 10:1 Gear - doublesided shaft - Pololu 3071

Polol' s miniature high power engine with durable carbon brushes. It has a 10:1 transmission, speed is 3000 rpm, torque is 0.3 kg*cm (0.029 Nm). It has an extended shaft...HPCB Motor with 50:1 Gear - doublesided shaft - Pololu 3073

Polol' s miniature high power engine with durable carbon brushes. It has a 50:1 gearbox, speed is 625 rpm , and torque is 1.1 kg*cm (0.1 Nm). It has an extended shaft...HPCB Motor with 30:1 Gear - doublesided shaft - Pololu 3072

Polol' s miniature high power engine with durable carbon brushes. It has a 30:1 transmission, speed is 1000 rpm , torque is 0.45 kg*cm (0.044 Nm). It has an extended...HPCB Motor with 30:1 Gear - Pololu 3062

Polol' s miniature high power engine with durable carbon brushes. It has a 30:1 transmission, speed is 1000 rpm, torque is 0.6 kg*cm (0.059 Nm).HPCB Motor with 298:1 Gear - doublesided shaft - Pololu 3079

Polol' s miniature high power engine with durable carbon brushes. It has a 298:1 gearbox, speed is 100 rpm , and torque is 5.0 kg*cm (0.49 Nm). It has an extended shaft...HPCB motor with 15:1 gear - 12V - Pololu 4788

A miniature engine from Polol from the powerful HPCB series. The motor is equipped with carbon brushes, which are more durable. The speed is 2200 rpm and the torque is...- Reduced price

- Promotion

HPCB Motor with 1000:1 Gear - Pololu 3070

Polol' s miniature high power engine with durable carbon brushes. It has a 1000:1 gearbox, speed is 32 rpm, and torque is 9.0 kg*cm (0.89 Nm).HPCB Motor with 10:1 Gear - Pololu 3061

High power miniature motor from Pololu with durable carbon brushes. It has a 10:1 gear ratio, speed is 3000 rpm, torque is 0.3 kg*cm (0.029 Nm).HPCB Motor with 150:1 Gear - doublesided shaft - Pololu 3076

Polol' s miniature high power engine with durable carbon brushes. It has a 150:1 gearbox, 200 rpm , and 2.9 kg*cm (0.28 Nm) torque. It has an extended shaft for mounting...HPCB Motor with 75:1 Gear - doublesided shaft - Pololu 3074

Polol' s miniature high power engine with durable carbon brushes. It has a 75:1 transmission, speed is 400 rpm , and torque is 1.6 kg*cm (0.15 Nm). It has an extended...HPCB Motor with 75:1 Gear - Pololu 3064

Polol' s miniature high power engine with durable carbon brushes. It has a 75:1 transmission, speed is 400 rpm, and torque is 1.6 kg*cm (0.15 Nm).HPCB Motor with 150:1 Gear - Pololu 3066

Polol' s miniature high power engine with durable carbon brushes. It has a 150:1 gearbox, 200 rpm, and 2.9 kg*cm (0.28 Nm) torque.HPCB Motor with 100:1 Gear - doublesided shaft - Pololu 3075

Polol' s miniature high power engine with durable carbon brushes. It has 100:1 transmissions, 320 rpm , and 2.2 kg*cm (0.21 Nm) torque. It has an extended shaft for...HPCB Motor with 1000:1 Gear - doublesided shaft - Pololu 3080

Polol' s miniature high power engine with durable carbon brushes. It has a 1000:1 gearbox, speed is 32 rpm , and torque is 9.0 kg*cm (0.89 Nm). It has an extended shaft...298:1 Micro Metal Gearmotor HPCB 12V with Extended Motor Shaft - Pololu 3056

Polol' s miniature high power engine with durable carbon brushes. It has a 298:1 gearbox, speed is 100 rpm and torque is 5 kg*cm (0.49 Nm). It has an extended shaft for...100:1 Micro Metal Gearmotor HPCB 12V with Extended Motor Shaft - Pololu 3052

Polol' s miniature high power engine with durable carbon brushes. It has a 100:1 transmission, 330 rpm, and 1.3 kg*cm (0.12 Nm) torque. It has an extended shaft for...HPCB Motor with 210:1 Gear - doublesided shaft - Pololu 3077

Polol' s miniature high power engine with durable carbon brushes. It has 210:1 transmissions, 140 rpm , and 3.6 kg*cm (0.35 Nm) torque. It has an extended shaft for...10:1 Micro Metal Gearmotor HPCB 12V - Pololu 3037

Polol' s miniature high power engine with durable carbon brushes. It has a 10:1 transmission, speed is 3000 rpm, torque is 0.3 kg*cm (0.03 Nm).5:1 Micro Metal Gearmotor HPCB 12V with Extended Motor Shaft - Pololu 3047

Polol' s miniature high power engine with durable carbon brushes. It has a 5:1 transmission, speed is 6000 rpm, torque is 0.1 kg*cm (0.01 Nm). It has an extended shaft for...75:1 Micro Metal Gearmotor HPCB 12V - Pololu 3040

Polol' s miniature high power engine with durable carbon brushes. It has a 75:1 transmission, speed is 400 rpm, and torque is 1.6 kg*cm (0.15 Nm).150:1 Micro Metal Gearmotor HPCB 12V - Pololu 3042

Polol' s miniature high power engine with durable carbon brushes. It has a 150:1 gearbox, 200 rpm, and 2.9 kg*cm (0.28 Nm) torque.5:1 Micro Metal Gearmotor HPCB 6V - Pololu 3060

Polol' s miniature high power engine with durable carbon brushes. It has a 5:1 transmission, speed is 6000 rpm, torque is 0.1 kg*cm (0.01 Nm).298:1 Micro Metal Gearmotor MP 6V with Extended Motor Shaft - Pololu 2385

Polol's miniature medium-power motor with a 298:1 gearbox, 75 rpm, 3.3 kg*cm (0.32 Nm) torque. It has an extended shaft for mounting speed sensors.See also

Pololu HPCB micro motors with carbon brushes: a long term solution

The micro HPCB (High Power Carbon Brush) electric motors offered by Pololu are a twin product to the HP (High Power) series. This means that both series are characterized by high motor capabilities, but these HPCB products are distinguished by the use of a different type of material. The brushes are not made of precious metals, but of carbon fibre (carbon). This gives the engine much more reliability and longevity. These components are used by experienced engineers in projects where high reliability and long life are important. They are also an excellent solution for people who intend to use the same components for multiple projects, simply by reassembling them inside subsequent devices. It is very common for engineering students to buy durable components that can serve them throughout their studies for many tasks - this allows them to save significantly and work with high-end components. For example, a motor with well-chosen parameters will be able to prove itself as a drive for wheels in a mobile robot, and then act as a drive for a robotic arm.

What you will find in this category?

In our offer you will find DC motors with great possibilities. They are characterized by high performance (speed and force), but this is associated with higher energy consumption. It is therefore worth taking care of the appropriate power supply for such components. Motors in this category, depending on the model, require a power supply of 3 V to 12 V (the most common values are from 3 V to 9 V). During uniform, no-load operation, they consume a small amount of current, which also depends on their capabilities and the solutions used - usually 60 mA, 100 mA or 120 mA. When the motor is loaded (for example during start-up), it can consume even several times more current. For example, a motor with a torque of 1.6 kg*cm and a ratio of 75.81:1 needs 1600 mA when the shaft is stopped, while it consumes 120 mA during steady operation. The offered motors have a built-in gear ratio, which significantly extends their capabilities. Thanks to the appropriate design, the devices can lift much heavier loads (at the expense of reduced speed). In our assortment we have motors with gear ratios of 30:1, 50:1, 75:1, 150:1, 298:1, and even 1000:1. Torque also plays a very important role, which is an indicator of the actual capabilities of the motor. For example, a device with a torque of 1.1 kg*cm is able to lift a maximum weight of one kilogram suspended no more than 1 cm from the shaft axis. We offer devices with torques of 0.45 kg*cm, 0.6 kg*cm, 1.1 kg*cm, 1.6 kg*cm, 2.9 kg*cm, 5 kg*cm, 9 kg*cm. These motors are able to generate 32 rpm, 100 rpm, 200 rpm, 400 rpm, 625 rpm or even 1000 rpm (depending on the model). In this type of products, the weight and size of the components play a very important role, since they are most often used for small devices. All offered products do not exceed the weight of 10 g, the diameter of the shaft is 3 mm, the diameter of the whole is 12 mm and the length of the whole component is usually 24 mm. The exception are those motors, which are equipped with a double-sided shaft (then the value of the total length is already 26 mm). The double-sided shaft is actually an extension of the shaft to the other side of the motor, thanks to which the constructor is able to place an encoder on it (a device allowing to receive feedback directly from the effects of the motor).