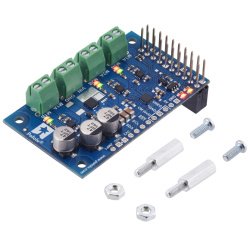

In category Motors Pololu micro series LP – Low Power you will find high quality engines for use in the broadly defined electronics and robotics. Pololu a world-class manufacturer of components used in robotics – its products are of great attention to detail and high strength. Each design product is carefully designed and then conducted a detailed analysis of its quality at all stages – from preliminary plans through production, to reports from users. Series motors are characterized by Low Power reduced power consumption compared to products from the High Power. This property, however, has its consequences in the form of a small device capabilities – but it must not be taken as a drawback, just a feature of specific solutions. The range of this series is also slightly smaller financial requirements from customers during shopping.

Pololu micro engines LP - Low Power

Micro Metal DC Geared Motor with Lead Screw (6V 150RPM M4*55)

Small metal motor supplied with 6 volts and 55 mm long M4 threaded output shaft. The idling speed is approx. 150 rpm. Its dimensions are: 25 x 12 mm .Motor with 1000:1 Gear - Pololu 1596

A miniature motor from the low power series by Pololu with a 1000: 1 gearbox, has 14 rpm, the torque is 5.0 kg * cm (0.490 Nm).Micro metal gearmotor 298:1 45RPM - Pololu 1094

Pololu's miniature low power series motor with 298:1 gearing, has 45 RPM, torque is 2.9 kg*cm (0.284 Nm).Motor with 30:1 Gear - Pololu 993

A miniature motor from the low power series by Pololu with a gearbox of 30: 1, has 440 rpm, the torque is 0.28 kg * cm (0.027 Nm).Motor with 30:1 Gear - doublesided shaft - Pololu 2202

A miniature motor from the Pololu low power series with a 30: 1 gearbox, has 440 rpm, the torque is 0.3 kg * cm (0.029 Nm). It has an extended shaft that allows the...Motor with 50:1 Gear - Pololu 1098

A miniature motor from the low power series by Pololu with a 50: 1 gearbox, has 250 rpm, the torque is 0.5 kg * cm (0.049 Nm).Motor with 100:1 Gear - Pololu 992

A miniature motor from the low power series by Pololu with a gearbox of 100: 1, has 120 rpm, the torque is 0.9 kg * cm (0.882 Nm).Motor with 75:1 Gear - Pololu 2360

A miniature motor from the low power series by Pololu with a gearbox of 75: 1, has 170 rpm, the torque is 0.6 kg * cm (0.058 Nm).Motor with 100:1 Gear - doublesided shaft - Pololu 2204

A miniature high-power motor by Pololu with a gearbox of 120: 1, has 120 rpm, the torque is 0.9 kg * cm (0.088 Nm). It has an extended shaft that allows the installation of...Motor with 150:1 Gear - Pololu 1097

A miniature motor from the low power series by Pololu with a gearbox of 150: 1, has 85 rpm, the torque is 1.2 kg * cm (0.117 Nm).Motor with 298:1 Gear - doublesided shaft - Pololu - 2208

A miniature high-power engine by Pololu with a gearbox of 298: 1, has 45 rpm, the torque is 2.9 kg * cm (0.284 Nm). It has an extended shaft that allows the installation of...Motor with 10:1 Gear - Pololu 1099

Miniature motor from the low power series from Pololu with a 5: 1 gearbox, has 1300 rpm, the torque is 0.14 kg * cm (0.013 Nm).Motor with 50:1 Gear - doublesided shaft - Pololu 2203

A miniature motor from the low power series by Pololu with a 50: 1 gearbox, has 250 rpm, the torque is 0.5 kg * cm (0.049 Nm). It has an extended shaft that allows the...Motor with 5:1 Gear - Pololu 1100

A miniature motor from the low power series by Pololu with a 5: 1 gearbox, has 2500 rpm, the torque is 0.07 kg * cm (0.007 Nm).See also

The motors are Pololu micro series Low Power – for whom and for what

Electric drives-is, above all, equipment for electronics, robotyków and craftsmen of various kinds. Such components are szczoteczkach electric, or in cars, toys for children. This series of motors resulting in Low Power-this is a great tool for creating devices with low power consumption. This, in turn, can potentially defer for a long time of the entire device or reduction of its weight and size (due to the possibility of using a smaller number of links). Less power and speed are features that contribute to their use for toys that can use children equipment less power is safer. Engines from the manufacturer Pololu is also very willing to choose the product of students of technical universities. Proven themselves in many projects and are characterized by high strength, which ultimately leads to savings (no need for frequent purchases of these items). The company Pololu except engines offers customers many other thoughtful and well-designed items that can be useful during construction, for example, a mobile robot. It is, among other things, items such as plastic wheels, motor drivers, encoders, ready, picked up the mounts for motors, or even all the work (for example, minisumo).

What we offer in this section

Our product range includes a large selection of motors resulting in Low Power series. They differ primarily by the type of transmission that affects torque and speed of rotation. Some models slightly differ in size – the diameter of the device all the same, but the length there dimensions 24 mm, 30 mm and 35 mm, weight varies depending on model from 10 g to 16 g (often about 10 g), and the shaft diameter is usually 3 or 4 mm Voltage motor power supply leads varies from 1 V to 9 V, but most often it is from 3 V to 9 V. the Equipment of this type consumes a minimum current, when already in motion and it is not load – these values are specified in the specification. Depending on the model, power can be 30 mA, 35 mA, 40 mA and 70 mA. For example, in the engine, the intensity of which is determined at 40 mA, the gear ratio is 50:1, and torque is approximately 0.5 kg*cm – at start-up of the shaft, the current consumption may be about 360 mA (dziewięciokrotność 40 mA). The stated reducers for individual models 5:1, 10:1, 30:1, 50:1, 75:1, 100:1, 150:1, 210:1, 250:1, 298:1 and 1000:1. Torque determine the capabilities of the engine, for example, the engine, which torque specified 0.5 kg*cm, will be able to work efficiently, holding up to 0.5 kg at a distance of one centimeter from the axis of the shaft. Increase the distance or exceeding this load is exceeding the capabilities of the device. In stock we have engines in which the torque values in the range of from 0.1 kgf*cm, 0.3 kg*cm 0.5 kgf*cm, 0.6 kg*cm, 0.8 kg*cm, 0.9 kg*cm, 1.1 kg*cm, 1.2 kg*cm, 1.9 kg*cm, 2.3 kg*cm, 2.9 kg*cm or 5 kg*cm As a mechanical box, and torque have the gear ratio on the number of revolutions, which the engine is able to run at a certain time – in offer we have devices that allow 14 rpm, 45 rpm, 50 rpm, 60 rpm, 85 rpm, 120 rpm, 150 rpm, 170 rpm, 220 rpm, 250 rpm, 440 rpm, 1300 rpm and 2500 rpm. the Part models are equipped with a so-called bilateral shaft – this means that beyond the protruding shaft, which is the main element of a drive on the other side of the engine, is a much smaller element of the shaft, on the basis of which you can read its current speed of rotation (for example, using sensors). The collected data can be used for feedback control.